About Us

Our Mission

Formed by a love of our planet, humanity and our collective health. When our founders learned of thebhealth risks assocuated with asbestos fibre cement sheets, they set out to formulated and make available an alternative that will never make you or your loved one sick. Enter, Corrucrete!

Our global health is still to thisbday the sole driving force behind everything that we do. And we won't stop until all asbestos cement is far from the lungs of all species upon planet earth.

Availability

With a 37 year history we have our supply network down to a fine art. We have made our products available world wide directly from your head office.

Info@corrucrete com

Sales@corrucrete.

The Product & Applications

Fibre cement roofing sheets, also known as fibre cement board or cement sheets, are a very reliable, versatile roofing solution. They’re especially popular for agricultural buildings but can also be used on commercial or industrial properties as well as on residential. And We’re proud to disrupt the market with our proprietary formulated ultra high performance concrete, corrugated wall and roofing panels; with a fantastic range of colours at competitive prices.

From agricultural and industrial use to domestic and commercial uses; fibre cement roofing sheets are quick and easy to install and come in large sizes that speed up the installation of roof & wall systems.

37 Years in the making.

Moral Responsibility

We noticed the inevitable health risks with asbestos in the early 1980s and decided to offer an alternative product in order to curb the effects of unethical businesses and business people. CORRUCRETE

What are Fibre Cement Roofing Sheets?

Fibre cement has been used as a building material for well over 100 years, initially reinforced with asbestos fibres & its original use was as siding for residential properties. Its uses have only grown thanks to a number of remarkable advancements, one being the development of glass reinforced concrete by RPC & particularly George Halliday, a chemist and engineer. He advanced cementitious cladding panel industry, included within that would be the means to form or profile wet, glass fibre reinforced concrete into corrugations.

Glass fibre concrete sheets are extremely sturdy, with an exceptional lifespan expectancy of over 100 years. They also have fantastic fire resistance as they are non-combustible, and work incredibly well as a roofing material, or as both internal and external cladding.

Fibre concrete sees use in all building types, including agricultural buildings such as barns or stables, warehouses, garages, schools and many more. Its ability to withstand the most extreme weather conditions and temperatures has also made it popular worldwide in all climates. Corrucrete sheets come in all shapes and sizes and are rather simple to cut and install. Unlike other types of roofing or wall panels, they come in generously large sizes, making them ideal for use on large buildings.

Our Panel

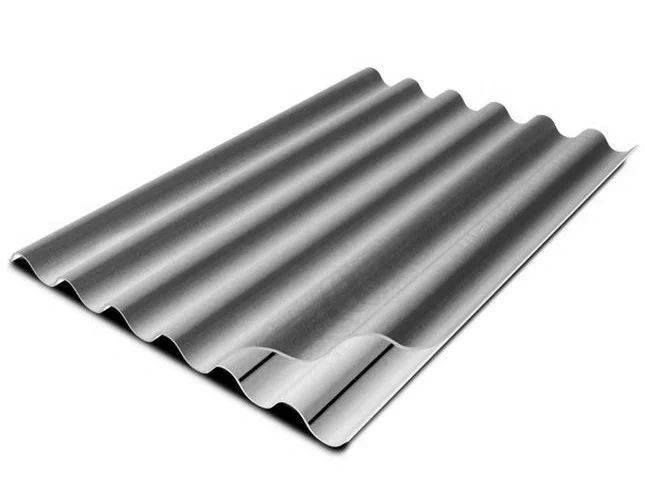

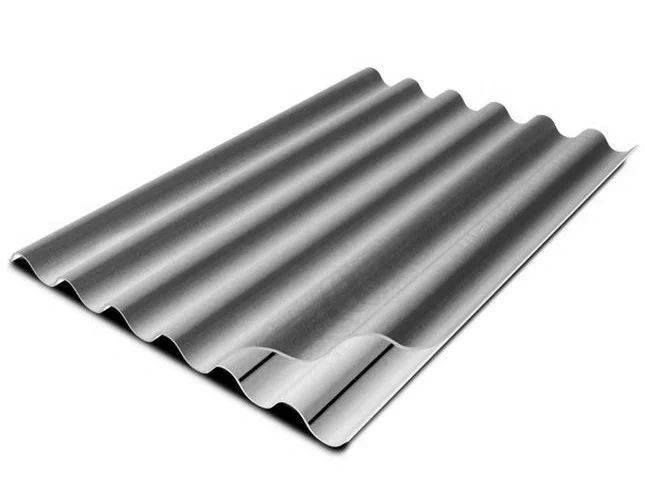

Corrugated Wall & Roof Panels

Resistant, durable, reliable and even environmentally friendly: Corrucrete is one of the most advantageous products for both roof and wall solutions for buildings. The cement matrix reinforced with glass fibers results in a malleable product that exceeds modern construction requirements. The proprietary formulation promotes high resistance to tensile stresses, buckling and impact that ultimately ensure a very long product life cycle.

Manufactured under pioneered technology for non- asbestos fiber cement corrugated sheets, The production process is streamlined and lean; all the material processing, dosing and product formation are under strict quality control and requirements for minimal tolerances. Our Corrugated cementitious panels are all completely ASBESTOS FREE. Reinforcement material is glass fibre manufactured and supplied by the world famous manufacturer of fibre reinforcement "St. Gobain".

A profiled sheet with the addition of corrugations dramatically increases its strength. Large format roofing sheets and cladding panels employ simple principles to create a strong weather-proof vertical and pitched profiled sheet cladding.

The preferred choice

In the UK, profiled sheets used either as a vertical cladding or as roofing was the ubiquitous product throughout the middle 3rd of the 20th century. Corrugated sheet were common as an industrial roofing, agricultural roofing or as storage and warehouse roofing.

The choice of corrugated fibre-cement for roofing and cladding was largely as a result of its rot proof and rust proof qualities, a particular advantage in acidic environments.

Growing Demand

Increasing demand for colour from around the 1950’s lead to the development of factory-applied coatings. Which we have employed but we always recommend integrally pigmented cement as the basis of our clients decision in regards to colour.

Proprietary

Unique Selection of raw materials, proprietary formula & manufacturing process is another key to our non-asbestos fiber concrete corrugated sheets superiority over fibre cement.

Panel Options

Colour Palette

Our UHPC Corrugated sheets are available in 18 standard integral colours. If you don't see what your looking for, ask us about custom colours.

Profiles

Currently our corrugated cement sheets are only available in two profiles. 4.2 and T.T. both of which have been designed to be identical replacements for the cancerous asbestos fibre cement sheets found commonly around the globe.

Profiles

Our profiles are exact replicas of 4.2 and Trafford Tile, perfect for replacement of asbestos reinforced corrugated panels.

Profile 1: Commonly used on all types of building for both roofing and vertical cladding applications.

Profile 2: is designed for roofs of 5° pitch and over and for vertical profiled sheeting in both single skin and insulated constructions. Profiled sheeting provides good resistance to aggressive atmospheric conditions .

Profile 3: or Profile 177/51 has a very broad appeal. This profile is most popular in the world which is widely used in residential building, agriculture and industrial application. Profile 7 with pitch of corrugation is 177 mm and overall depth is 51 mm. Profile 7 is designed for roofs of 5°

The reason for the distinction between profile 2 and profile 3 is due to the difference in pitch of corrugation and overall depth. Profile 7 (177/51) is with longer pitch and higher depth than Profile 3 (130/35).

Manufacturing

General Production Process

Stage 1: Preparing material & reinforcement

Stage 2: Preparing molds

Stage 2: Pulp

Stage 3: Slurry preparation/mix

Stage 4: FR Concrete layup within molds

Stage 7: Screed wet panel to desired thickness

Stage 8: Stacked curing/pressure process

Stage 7: Panel cutting

Stage 8: Panel hydrophobic sealer application

key Benefits

Long Lifespan

The real benefit to Corrucrete board's longevity comes when you compare it to other siding materials. Corrucrete boards go above and beyond what other materials can provide by outlasting the competition.

Corrucrete is actually stronger and more durable than any competitive material. As a result, it has the same durability as brick or stone. And just as with a brick or stone, Corrucrete will last longer than the structure it's installed on.

Maintenance Free & Energy efficient, unlike wood siding, Corrucrete does not rot or require painting to keep its colour. It is fireproof, insect resistant, and performs well in natural disasters.

Planet Health

The main reason why Corrucrete is becoming more and more popular is sustainability. It is already proven to last nearly 40 years in real world, still installed, conditions throughout North America. The technology itself is a hyper-performing concrete, while traditional concrete is expected to have a life span of 100+ years and most building materials only lastinmasomehwere between 20 and 50 years before needing to be replaced. Corrucrete is likely to push the limits of 1,000 years. Leaving no need to replace or demolish the buildings which it protects. As one of the longest lasting materials When it comes to eco-friendliness. Despite using a lot of water during production, fiber cement relies on recycled materials and consumes fewer resources.

Extreme Weather

Weather changes can damage a building structure over time. By using the Corrucrete, buildings are protected by a littoral shield of UHPC concrete that offers high stability and strength, all year round.

Picking the right siding for your project is a delicate balancing act between aesthetics, durability, maintenance, and affordability. With Corrucrete, you can get way more than you could ever pay for.

Cladding & Replacement of Asbestos Panels

Additional Information

1. Highly cost effective

Unlike the building materials available in the market, Corrucrete roofing sheets are cost-effective in every possible manner. Fiber cement roofing sheet is quite a robust roofing solution. They won’t rot or decay due to weather conditions, thus, making an ideal solution to use in the exposed areas. Once installed, they will also last for up to 1,000 years.

3. Fire resistant

The natural fire-resistant property of fibre cement sheets make it perfectly ideal for roofing solution. Corrucrete is 100% non-combustible.

4. Safety

Sheets made by components without asbestos, it is safe for human health and friendly environment.

5. Low maintenance

Designed to be highly robust and resist nearly any problem that roofing or walls are expected to encounter. Corrucrete fiber cement sheets require no maintenance other than a simple powerwash once every few years. All you’ll need to do is give it an occasional clean to remove excess dirt and debris. This is best done using soft sponges, water, and mild detergent and a gentle power wash.

Our Offering

Corrucrete façade panels offer the designer a wide range of creative freedom in designing both roofs and facades. The panels can be installed with the corrugations running vertically or horizontally. The panel edges can be lapped or the panels can be installed with open joints. This flexibility allows for multiple design options. Suitable for use on new buildings and refurbishments of every type and size. Corrucrete excellent physical and mechanical properties exceed European Standard requirements, which are the most stringent performance standards in the world.

100 Year + Life Expectancy

Sustainable & Energy Efficient Roofing

Additional Information

Quality of Fiber Cement Board

One of the most important benefits of fiber cement board are the strength and durability it provides. This type of material protects the home from wind and rain damage, and can even withstand hurricane level storms. In fact, fiber cement sidings outperform many siding competitors in a range of climates

We all know, the average lifespan of fiber cement siding is roughly 50 years, but not many of us have been able to see a 50 year old fibre cement installation. However, we are not truly a fibre cement, we are UHPC fibre concrete and have a proven installation record dating back 37 years. Panels still on walls that were installed nearly 40 years ago. As a result, it is likely that we will never need to replace the Corrucrete until about the year 3021, seriously it is highly likely that our panel with last up to 1000 years. Potentially yunring back into limestone before having to be removed from its structure. the same can not be said of traditional vinyl, wood, GFRC, High pressure laminate or any other cladding materials.

Cost of Fiber cement board

With the outstanding characteristics of our material it should be expected and has proven beneficial to our clients yo spend a little more money upfront in order to save a ton in the long run.

Wall Cladding Refrences

Roofing Refrences

Contact

1.888.808.2110

Corrucrete UHPC Cladding & Roofs

193 Lorne Avenue West, Stratford, Ontario N5A 6S4, Canada

Hours

Mon | 09:00 a.m. – 05:00 p.m. | |

Tue | 09:00 a.m. – 05:00 p.m. | |

Wed | 09:00 a.m. – 05:00 p.m. | |

Thu | 09:00 a.m. – 05:00 p.m. | |

Fri | 09:00 a.m. – 05:00 p.m. | |

Sat | Closed | |

Sun | Closed |

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.